Conti-tds

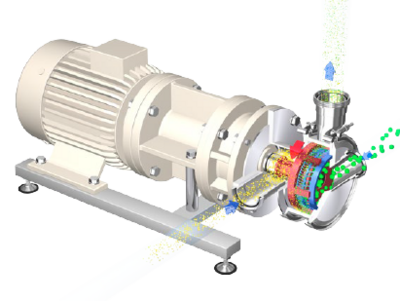

Increase the economic potential of your processes with YSTRAL Conti-TDS: Dust and loss-free container emptying, powder transport and addition, wetting and dispersion up to complete de-agglomeration can all be implemented using a single machine.

With YSTRAL Conti-TDS, powders are not only wetted, but dispersed in the liquid under vacuum. This inline mixing process avoids agglomeration. This offers you an optimised result with a better breakdown, higher raw materials efficiency and higher product quality.

Advantages

- The combination of different process steps in one machine provides you with great rationalisation potential: Production times are minimised, sub-processes are completely eliminated, production costs are reduced.

- Clean manufacturing process thanks to a dust and loss-free powder feed, even with powders that are difficult to wet, sticky or dusty

- Aspirating and dispersing of powders directly from silo (via buffer hopper), big bag, hopper, sack, barrel etc.

- No glued containers or built-in parts

- Fast and reproducible production of the products thanks to the immediate and complete breakdown of raw materials

- Inline Mixing: No ingress of external air, powder conveying under vacuum in dense stream

Technical data

- Power: 5.5 – 250 kW

- Voltage: 230 / 400 / 500 V, 50 Hz, custom voltages possible

- Speed: 1.500 / 3.000 min-1 stepless up to 3,600 min-1 with frequency converter

- dispersion chamber: Stainless steel 1.4404 (AISI 316 L), special material, swappable tools, quick release

- Liquid throughput: 10 - 200 m3/h

- Maximum viscosity: 200,000 mPas (subject to size and use in the machine)

- Seal: Configuration acc. requirements

- Options: Explosion-resistant design, certificate, qualifications

- Suction power powder: up to 24 t/h